Close the Loop On Wasted Water

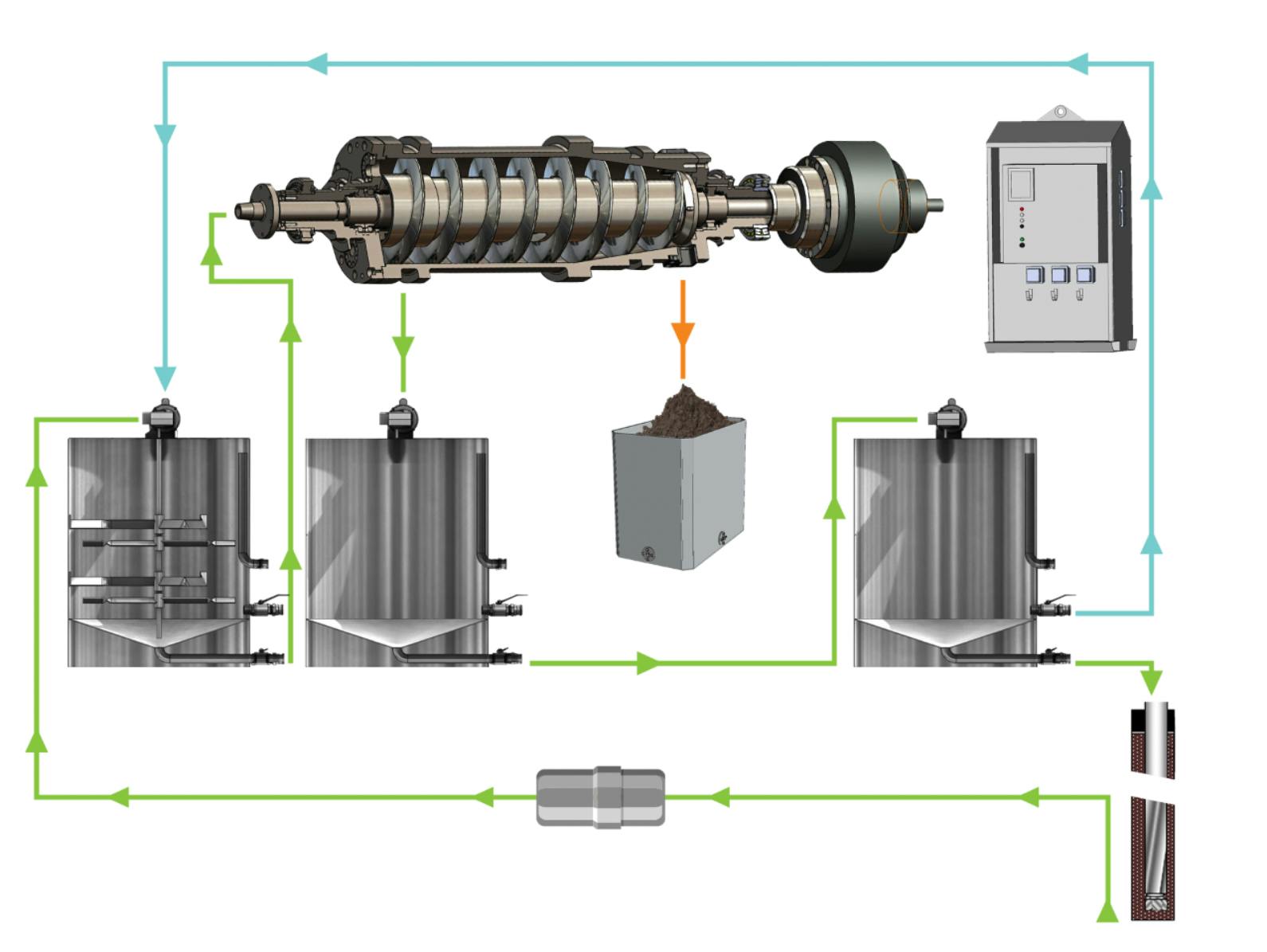

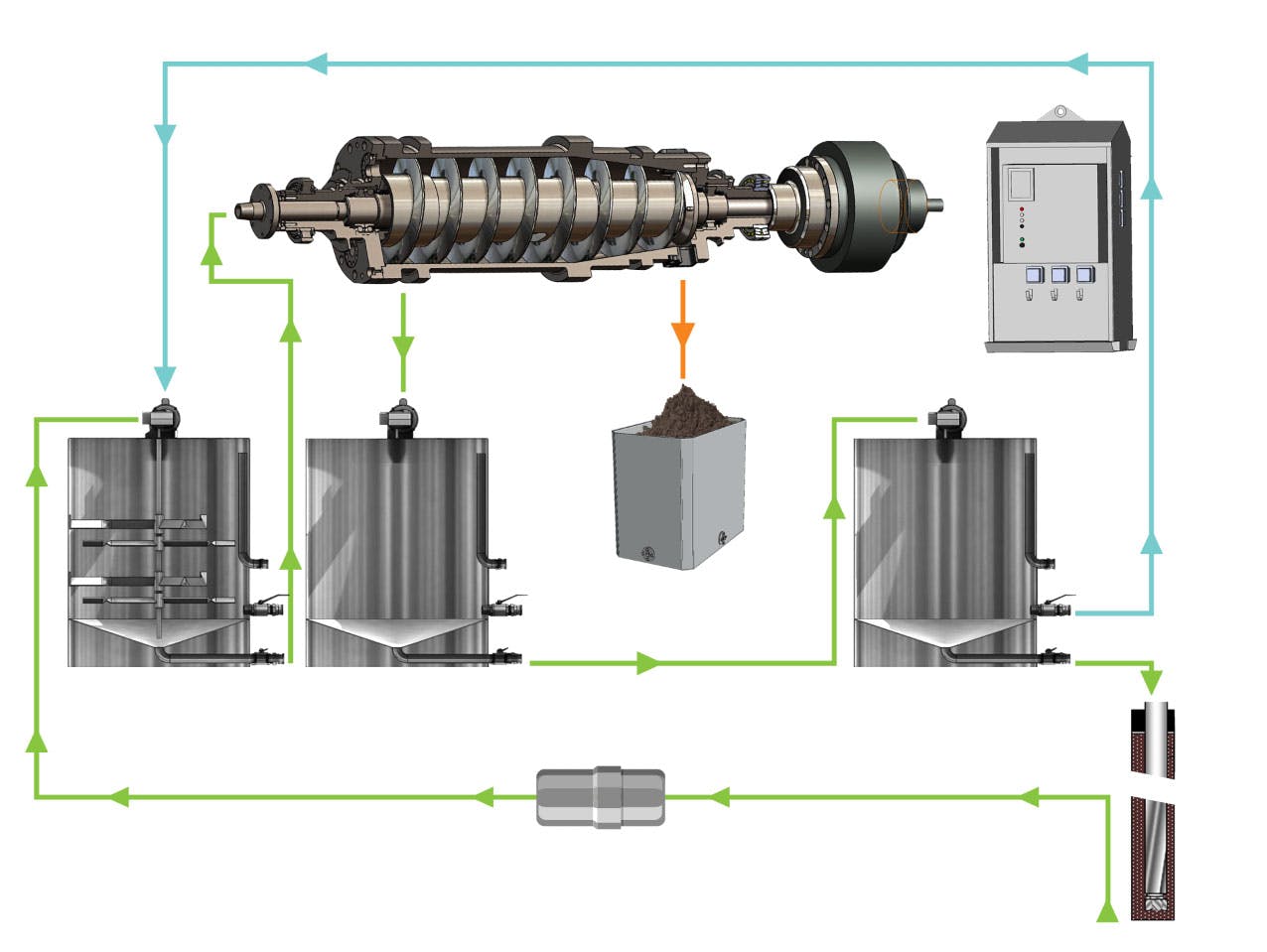

When you stop to consider the thousands of litres of water it takes to drill the average hole, the scale of your water needs is astounding. To complete an average 1000m NQ hole, you may be wasting up to 577,600 litres of water – just to reach depth. What if you could do the same with just 2,400 litres of water? With the SRS Centrifuge, this is possible. With no water discharge, the SRS Centrifuge is a closed loop system that separates liquids from solids down to the smallest micron. Clean water is returned to the drill, solids are easily stored and transported, and hundreds of thousands of litres of water are spared. If you could save all that water and increase productivity, why wouldn’t you?